Morris Chang: From Refugee to the Godfather of Taiwan's Semiconductor Industry

Morris Chang may not be a household name in the western world but his achievement is comparable to that of western business Titans like Rockefeller and Carnegie. His life consists of one miracle by another. After fleeing from China to the US during the China Civil War, he worked his way up to be the general manager of the Semiconductor businesses and 3rd ranked person of Texas Instrument -- one of the biggest semiconductors companies in the world. Chang was one of the first Chinese Americans to become top business leaders. In his 50s, he returned to Taiwan and founded Taiwan Semiconductor Manufacturing Company (TMSC) and became the "godfather" of Taiwan's semiconductor industry.

Chang was born in China in 1931. Most of his early life was deeply shaped by war -- he was forced to flee three times due to the Second Sino-Japanese war and China civil war. After the wars, he came to the United States at the age of 17 to study at Harvard University, a school that primarily focused on arts and humanities education. As an underrepresented minority ethnic group, most Chinese Americans at the time worked in low-end restaurants or laundry businesses. Academic jobs were the only few alternative options that would fit with Chang's mission of achieving big societal impacts. He later transferred to MIT in the hope of becoming a scholar in engineering majors. Unfortunately, he failed the qualifying exams twice at MIT and had to quit his academic path and went to the job market after obtaining his master's degree.

He entered the Semiconductor industry in his first job at Sylvania, an industry leader then. However, his team was dismantled three years later. He then moved to Texas Instrument, which was famous for the invention of integrated circuits (IC) and was fast-growing. After working at Texas Instrument for three years, he went back to Stanford to pursue a Ph.D. degree and then returned to Texas Instrument to continue his corporate duty. By the 1970s, Chang was already the general manager of the whole semiconductor business of Texas Instrument.

Chang was a keen observer of the semiconductor industry. While working at Texas Instrument, he observed that a lot of brilliant people in the company were hoping to create new businesses but heavy investment requirements prevented them from getting started. As chips became more and more sophisticated, the chip manufacturing business became super capital-intensive. The cost of creating a chip manufacturing line (also known as "foundry" or "fab") could easily be over 3-4 billion US dollars. Besides, new startups cannot maintain a sustainable stream of needs to keep their manufacturing line busy all the time, which is the only way to justify the heavy investments.

In contrast, chip designing requires much less capital. It would be a win-win situation if there is a "pure-play" company that focuses on manufacturing so that startups could focus on designing. This model of chip making process, also known as Fabless manufacturing as it features the split of designing and manufacturing, is crucial for the booming of the semiconductor industry. There were a lot of chip design talents in the US, but very few were good at both chip manufacturing and cost management. Chang was one of the few talents who had the expertise.

Chang started to face career setbacks in the early 1980s. At the time, Texas Instrument shifted focus away from semiconductors and became a diversified device manufacturer. Chang disagreed with the shift and had to leave the company. After the career setback, Change decided to turn his observation into action. At the same time, Taiwan government was eager to find ways to break into high-end industries like chip manufacturing. Chang was the perfect person to lead the cause. After a short stint at another company, Chang accepted the invitation from the Taiwan government to be the first chairman of the Industrial Technology Research Institute, an institute that played a critical role in the industrial transformation of the island. With the support of the Taiwan government, Chang founded the TSMC one year later. TSMC created a whole new industry of "pure-play" chip manufacturing (a.k.a., foundry industry). By focusing on only manufacturing but not designing, TSMC assured its partners, typically US chip designing firms, that TSMC won't compete with them or share their trade secrets with their competitors.

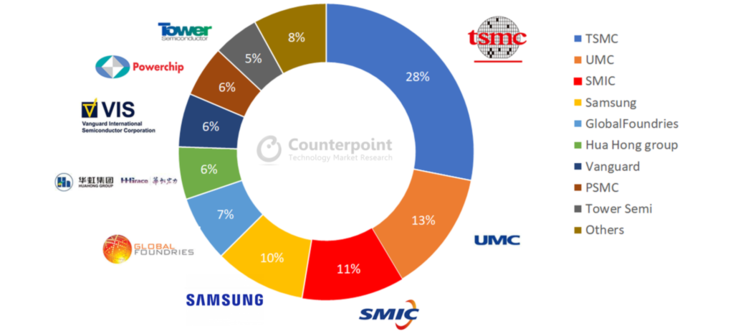

Now TSMC is undoubtedly the market leader in the industry and occupies 28% of the market share in a recent study. Also thanks to TSMC, Taiwan became crucial for the global semiconductor supply chain, which Bloomberg has recently published an article to illustrate.

Global semiconductor market share (image via Counterpoints Research)

In one of his recent talks, Chang gave a summary of what he thinks is the key reason for the TMSC's success. Chang attributed the success to three factors.

The number one is Taiwanese people’s hard-working spirit. For example, during his second stint at TMSC, Chang started the "nightingale program", which included both day and night shifts to ensure there were R&D activities 24/7. This program would be unimaginable in U.S. companies. According to Chang, this nightingale program was the key reason why the TSMC could eclipse all of its competitors in technology. In chip manufacturing, the size of the device the manufacturing process could produce is a key indicator of technology level -- smaller size means more devices in the same area but also is much harder to manufacture. After losing in the competition of the 14nm manufacturing process, TSMC reached the 10nm, 7nm, and 5nm manufacturing processes one by one in just a few years. Till now, none of its competitors have reached the 10nm milestone yet. Please refer to RISC-V, China, Nightingales for more details.

Figure. The timeline of manufacturing process in major foundry companies.

The second factor is the local professional management. This factor is crucial because chip manufacturing is operation-heavy and efficiency-driven. Chang also mentioned that managerial talent doesn't transfer well across borders because of culture and factors.

The third factor is the good infrastructure provided by the Taiwan government. It is easy to see how good infrastructure makes the transportation of goods much easier. Chang also mentioned an important point. The good high-speed railway and the small Island of Taiwan make it possible for talents to be relocated to any place within the island without the need to be separated from their families. The benefits of good infrastructure on the human management side are often ignored by governments but are crucial for businesses that require a lot of talent.

All the three points are about one thing: TSMC can attract a huge amount of disciplined and high-quality talent and can retain them through good management and providing a convenient life. The company has an envious 3-4% employee turnover rate. For those who leave for various reasons, they became the most sought-after talents in the industry. I also highly recommend this great essay by Kevin Xu based on Chang's talk.

Throughout his life, Chang overcame one challenge by another and successfully turned setbacks into new opportunities. Although he became a refugee three times in his youth, he immigrated to the US to pursue a new life. After failing in MIT Ph.D. qualifying exams and crumbling his academic pursuit, Chang entered the newborn semiconductor industry and worked tirelessly to become an expert in semiconductor manufacturing. After facing a career setback in Texas Instrument, he took the courage to leave the US, a place he had spent 36 years, to Taiwan for creating TSMC and became the godfather of the semiconductor industry of the Island.

Chang is also a great writer. I highly recommend his Chinese autobiography that covered his early life before 33 years old (unfortunately I haven't found any translated version yet). Besides, he is working on the second half of this auto-biography, and hopefully, will publish it soon. I am very much looking forward to reading it and will share a sequel in the future.